Extrusion blow and injection blow

Injection blow molding technology

This method consists of combining the injection technique with that of the blowing. The material is injected to form the preform that can incorporate the final screwing of the part. The preform may be stored, transported or directly heated then be blown to the desired shape.

The preform is then enclosed in a blow mold having the desired shape. One end of the preform is pinched. Compressed air is injected into the cavity through the preform opening so as to press the material against the cavity cooled and freeze the part in its final shape.

Material generally used is PET.

Impec Mold produces tools used for this technology :

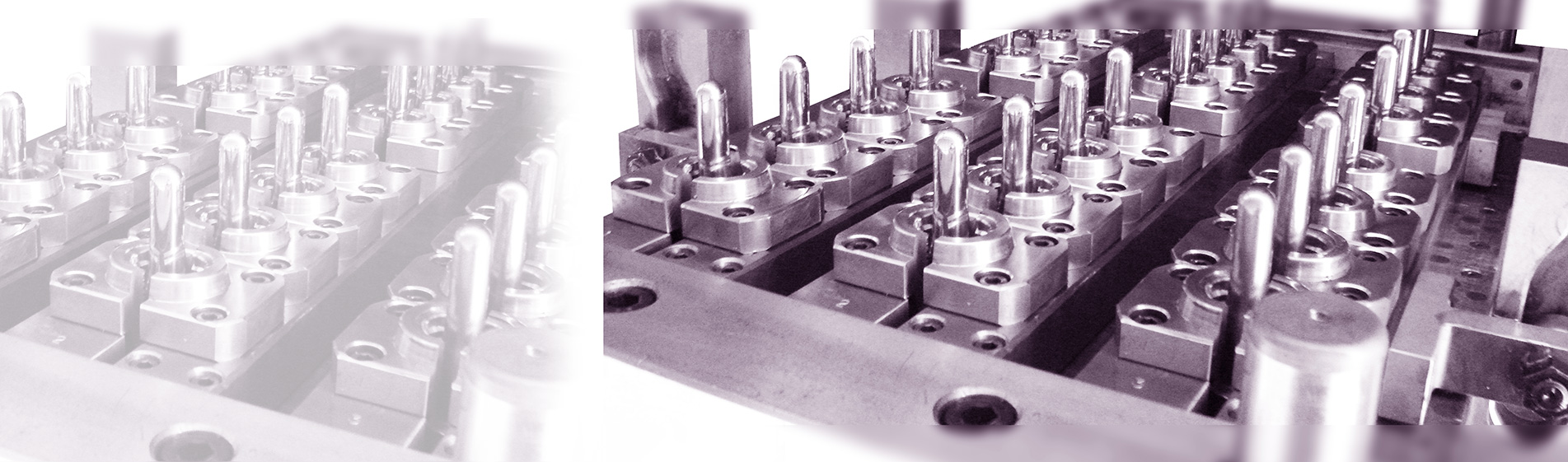

Moulds multi-cavities preforms

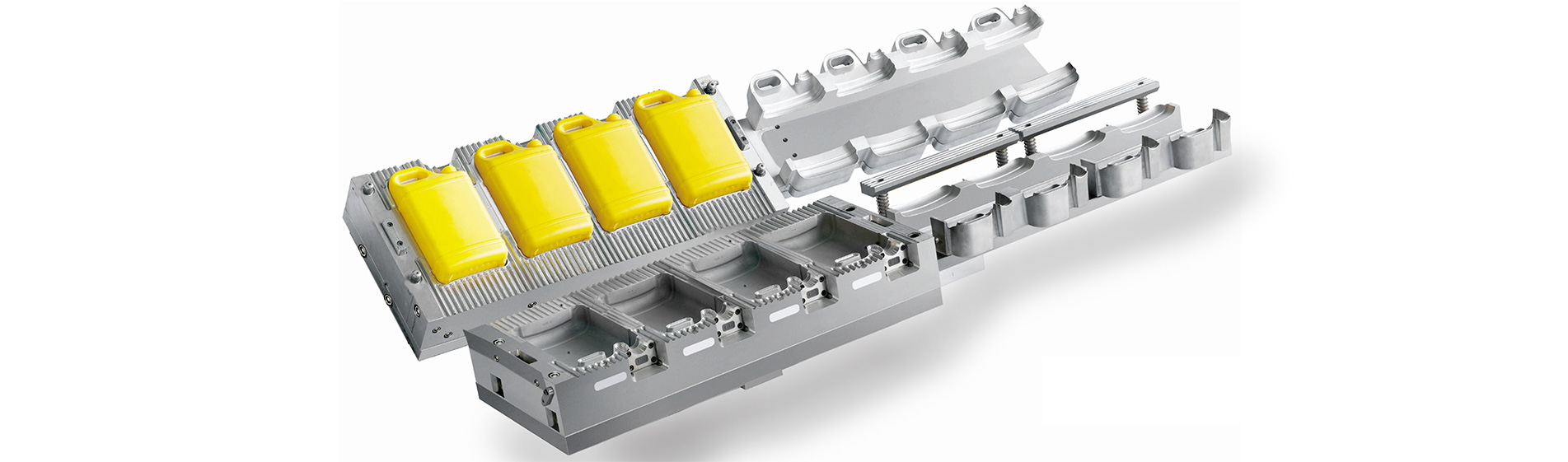

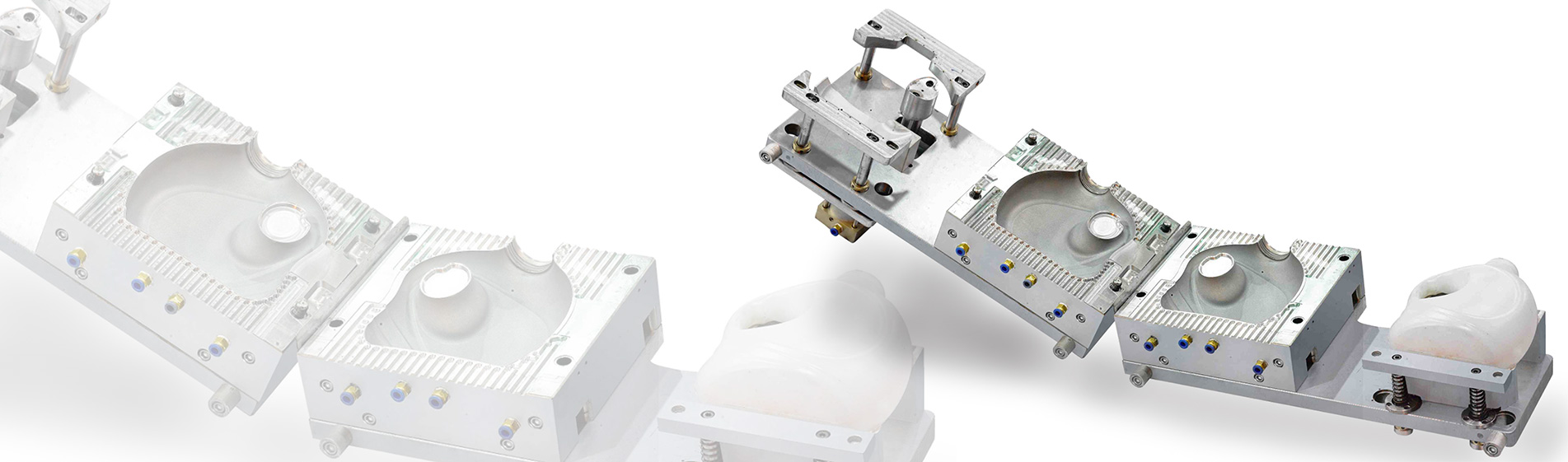

Blow Molds

Blow molding technology

This method combining the technique of extrusion with the blowing.

The extruded parison is enclosed in a blow mold in two half-shells having the desired shape.

The parison has an orifice at its end, which is pinched.

Pressurized air is blowing into the cavity through the hole in order to press the deformable tube against the cavity cooled and freeze the part in its final shape.

IMPEC MOLD carries tools used for this technology.

TECHNOLOGIE FONDERIE ZAMACK

ALUMINIUM

ALIAGE DE BRONZE